Manual Toggle Clamps from Wixroyd

What is...

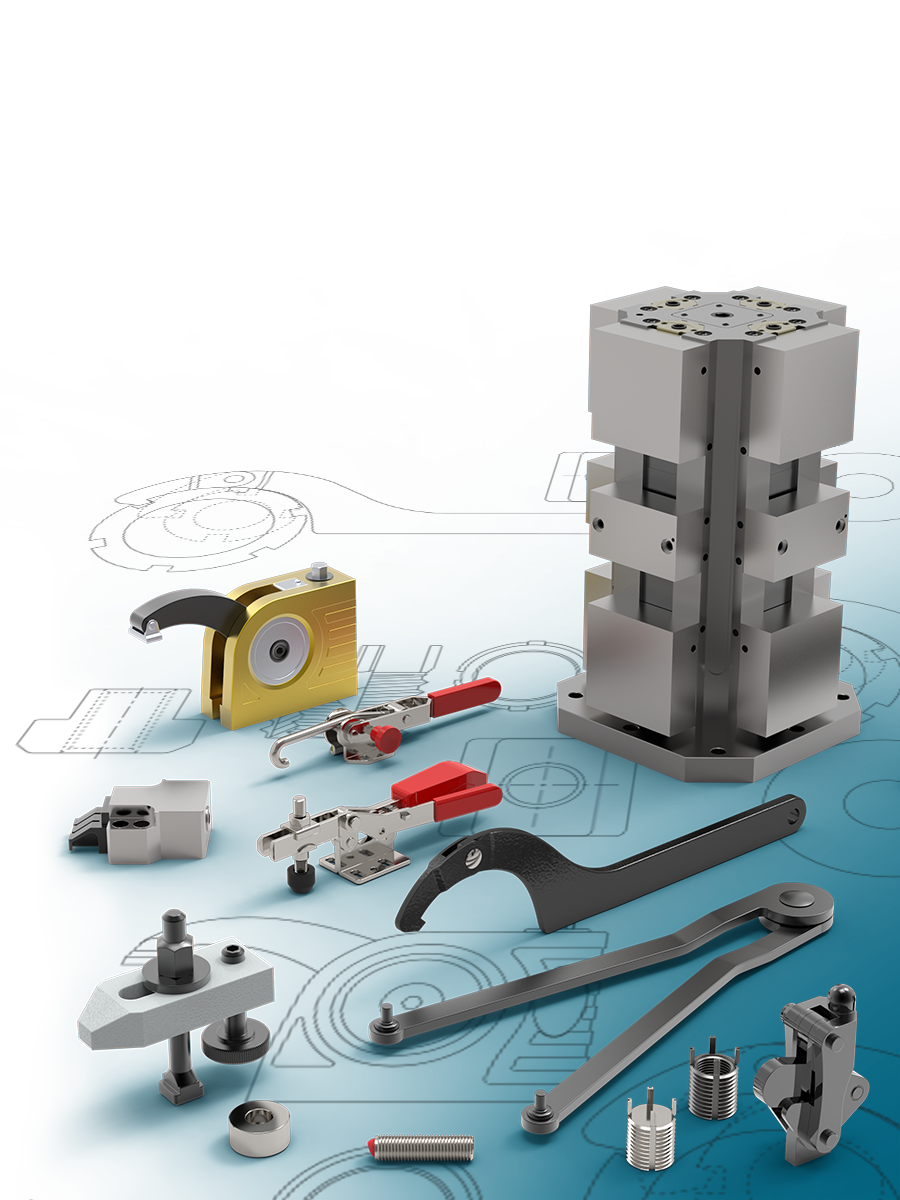

Toggle clamps are simple workholding clamps actuated by a toggle adjuster to determine workpiece. Manual version feature easily actuated, grease resistant handles for easy engagement or disengagement of workpieces. Our manual toggle clamps are available in horizontal, vertical, latch, push-pull and hook types. Stainless or safety lever versions are also available.

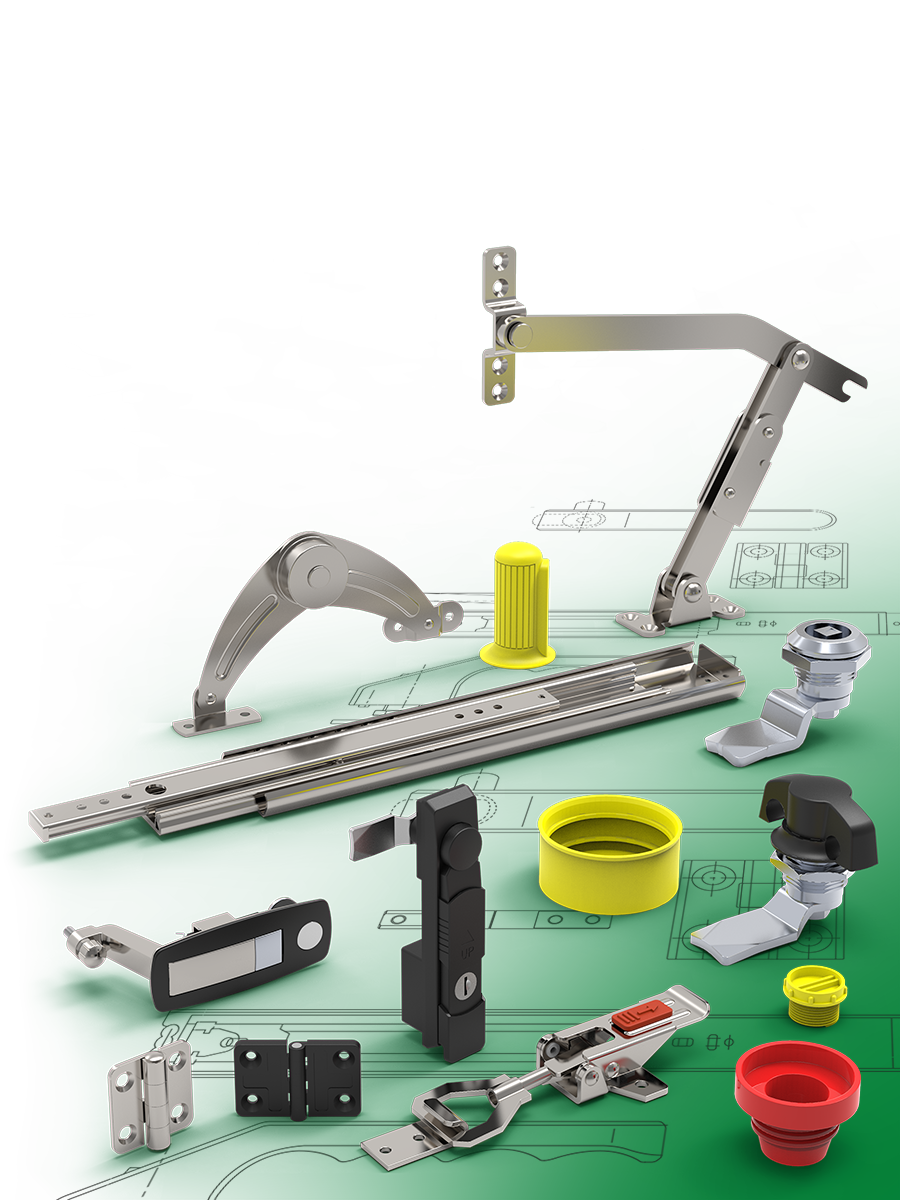

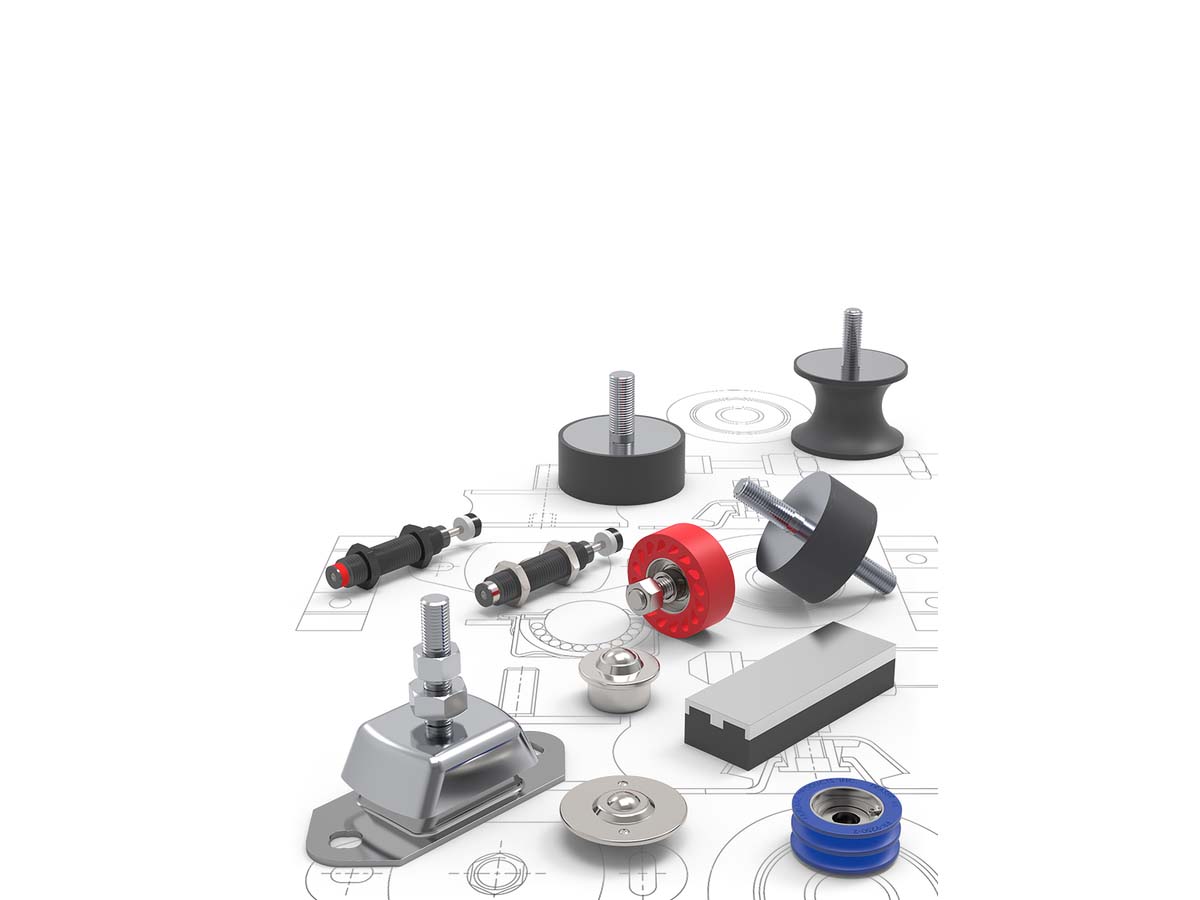

Wixroyd’s comprehensive range of machine elements, standard parts, access components and work holding equipment contains a broad selection of sizes in materials including; stainless steel, steel, die cast zinc as well as plastic. CAD models of Wixroyd components are available for free – visit CAD download. For a free copy of the latest Wixroyd catalogue, the designers indispensable guide to a range of endless possibilities, visit free literature.

Clamping or workholding is the means by which an object is held in place for further actions, such as machining, to be carried out upon that object. One of the most common examples of a workholding object is a vice (or 'vise', depending on where you're from!) - an object with parallel jaws that are ratcheted together to hold an item securely. However, in high-throughput situations, more rapid clamping/unclamping devices are necessary to minimise production time. In addition, for automated machining, workholding pieces are useful to correctly orientate or locate items before clamping and subsequent processing. The clamp or workholding device itself must hold the object firmly without damaging it.

Horizontal acting toggle clamps made from zinc plated and passivated steel or stainless steel. Bushes are made from case hardened and greased steel. Their easily actuated handles are made from grease resistant plastic.

Vertical acting toggle clamps made from zinc plated and passivated steel or stainless steel. Bushes are made from case hardened and greased steel. Their easily actuated handles are made from grease resistant plastic.

Latch type toggle clamps made from zinc plated and passivated steel or stainless steel. Their easily actuated handles are made from grease resistant plastic. Fixed catches are available seperately.

Push-pull manual toggle clamps with a compact design that maintains long travel length. Ideal for space efficient applications.

Fully stainless steel versions of our latch type toggle clamps. Supplied with appropriate stainless clamping screw and rubber nose. Stainless fixed catches available separately.

Fully stainless steel versions of our push-pull toggle clamps. Supplied with appropriate stainless clamping screw and rubber nose.

Fully stainless steel versions of our hook type toggle clamps. Supplied with appropriate stainless clamping screw and rubber nose. Stainless fixed catches available separately.

Features

Mounting Base Variations

Horizontal

Vertical

Angled

Clamping Variations

Vertical

Horizontal

Push-pull

Hook Type

Latch Type

Quality Features

Ergonomic 2-component handle

Stainless rivets and hardened bushings

Moveable stop for variable opening angle

Operator finger protection

Temperature resistant

Paint wetting impairment free

Unique Features

Safety latches

Heavy duty versions

Pneumatic clamping

Matte black surface for optical measurement

Technical Specs

Explanation of Toggle Clamp forces

Holding forces f1 or f2

The force transmitted to the workpiece by the Toggle Clamp's closed arm, without itself being deformed when machine forces are applied.

Holding force value is dependent upon proximity of the measuring point to the Toggle Clamp's pivot point (hence two values, f1 and f2 provided).

Clamping forces f3 or f4

The force applied to the workpiece when the Toggle Clamp's arm is closed. Clamping force can only be stated for Pneumatic Toggle Clamps - clamping forces of manual clamps can not be correctly measured as it is dependent upon the operator.

Piston forces f5

For pneumatically controlled Toggle Clamps only, f5 is the piston force required to achieve the stated clamping force.

Applications

Welding fixtures

Machining and jig assemblies

Cmm’s

Email Newsletter

Be the first to receive the latest news and exclusive offers via our newsletter.

Alexia House, Glenmore Business Park

PO19 7BJ Chichester

United Kingdom

0333 207 4497

sales@wixroyd.com

Route via Google Maps

Company registration no: 00496138

Company VAT number GB 408154022