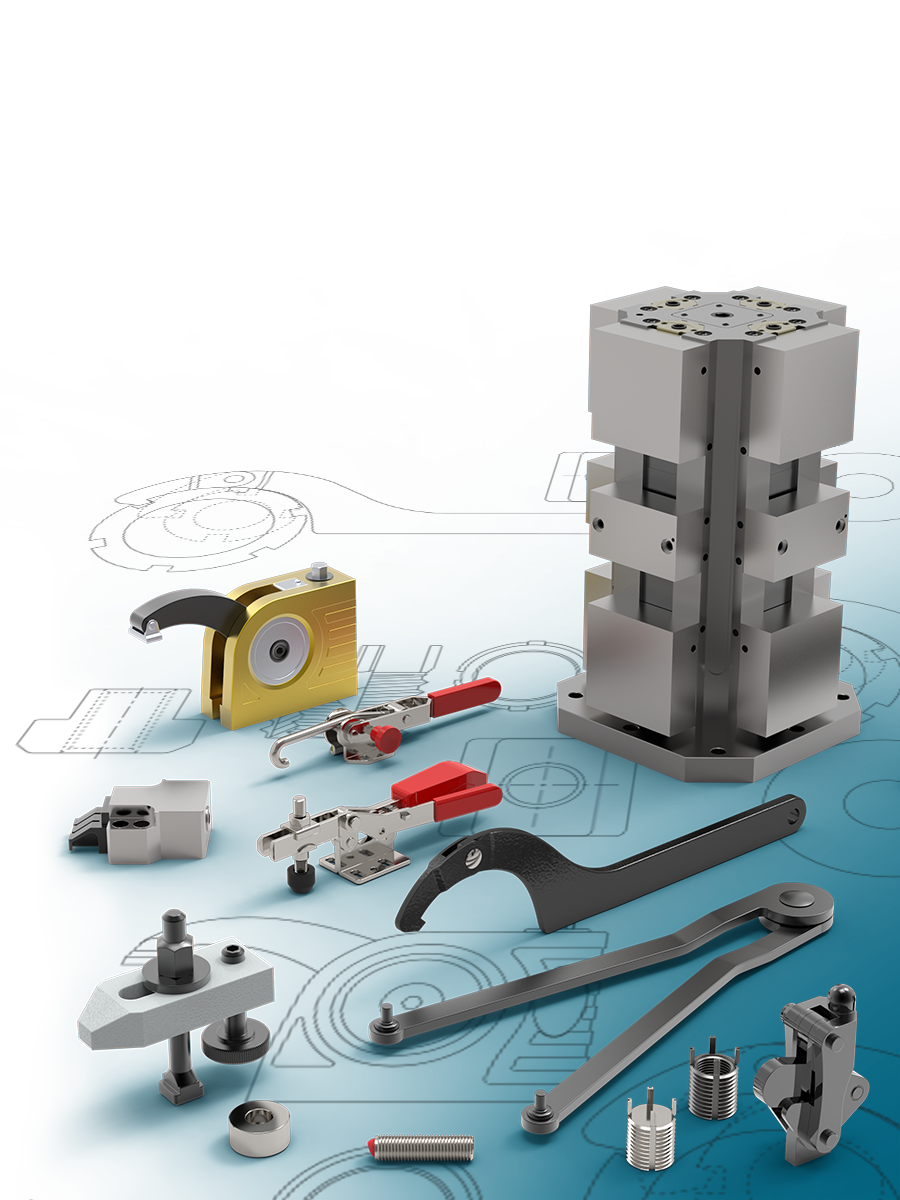

5-Axis Dovetail Fixtures

What is...

We know that workholding can be difficult because we face the same challenges.

Dovetail fixtures are a flexible workholding solution that has been utilised for years by some of the worlds leading manufacturers. Tested for strength.

Faster Job Setup

You can run a wide variety of parts and eliminate the changeover time. There is no need to spend time removing and replacing custom fixtures in your machines. We simplified the process.

Smaller dovetail fixtures can also be attached to larger ones, allowing you to switch to any size part as fast as you can turn a hand tool. We have made workholding easier for you.

General Guidance

Dovetail Fixtures Are Simple

Simply load your workpiece onto the fixture and hand-tighten the spring loaded clamp. Unloading is just as easy.

- Simple dovetail - A simple workpiece prep creates a dovetail that locks into the spring-loaded clamp.

- Spring loaded clamp - Spring-loaded clamp works with you to hold the part strongly and makes releasing easy.

- Hand tightened - Use a T-wrench to hand-tighten the clamp and you are done. It's quick, simple and strong.

- Strong by design - Solid, super-strong stainless steel ensures that the dovetail fixtures will hold up to repeated use.

- Fits any machine - We have adapters, risers and versions of dovetail fixtures to fit any machine you can think of. Yes, even that one.

Full Tooling - 5-Axis Manufacturing

A full access pass

Speed up your manufacturing by machining five, full sides of the workpiece in one set-up. The dovetail design quickly locks the part in place for extreme clamping strength and rigidity, without wasting much material on the base.

A locating pin ensures your part is positioned accurately and (unlike other products) the spring-loaded clamp can be tightened with a simple T-handle wrench. Quick and easy.

Dovetail Fixture gets out of your way so you can get the job done.

Less tooling, more manufacturing

Spend your time making parts, not figuring out how to hold them.

Technical Specs

Dovetail Fixtures - A range of options

Our dovetail fixtures are available in a number of sizes to best suit the size and weight of components you are manufacturing.

RPM + Feed Rates for Dovetail Cutters

When manufacturing dovetail detail on material blanks and are using our dovetail cutters, please take note of the suggested RPM and feed rates for the variety of materials.

| Workpiece material | Cutting speed | 1/4†diameter | 3/8†diameter | 1/2†diameter | 3/4†diameter |

| Aluminium | 1600-2000 | 0,0025 | 0,0045 | 0,0060 | 0,0075 |

| Gray cast iron | 490-590 | 0,0008 | 0,0012 | 0,0018 | 0,0024 |

| Soft steels > 35Rc | 295-390 | 0,0008 | 0,0012 | 0,0018 | 0,0024 |

| Alloy steels 4130-4340 | 250-450 | 0,0016 | 0,0025 | 0,0031 | 0,0037 |

| Tool steels A2, D2, S7 | 150-300 | 0,0014 | 0,0020 | 0,0025 | 0,0032 |

| Die steels P20, H13 | 250-450 | 0,0016 | 0,0025 | 0,0031 | 0,0037 |

| SS 303 | 290-375 | 0,0008 | 0,0012 | 0,0018 | 0,0024 |

| SS 304, Invar, Kovar | 230-280 | 0,0007 | 0,0011 | 0,0017 | 0,0023 |

| SS 304L, 316L, 13-8Ph, etc. ... | 295-360 | 0,0006 | 0,0010 | 0,0016 | 0,0022 |

| Titanium 6AIV4, 6-2222 | 160-230 | 0,0006 | 0,0011 | 0,0014 | 0,0022 |

| High temperature alloys 718 inconel, A286, Haynes | 80-120 | 0,0006 | 0,0011 | 0,0014 | 0,0022 |

Dovetail preperation dimensions - Example

An example of dovetail preparation required on stock fillet, for use in a 0.5†dovetail fixture.

Installation

Dovetail preparation

1. Clean, even surface in dovetail cut

Correct:

Dovetail cutter has cleaned up entire surface. This leaves more of workpiece in contact with fixture for extra stability.

Incorrect:

Surface is cut unevenly, compromising rigidity.

2. Small edge break, not a sharp point

Correct:

Cutter should leave a small edge break. Exact measurements can be found in the dovetail preparation specs for your specific product.

Incorrect:

Dovetail edge comes to a sharp point interfering with proper fit.

3. Bottom surface of workpiece is smooth

Correct:

Workpiece bottom surface is smooth and free of burrs and ridges.

Incorrect:

Bottom surface of workpiece is left rough, interfering with proper clamping.

4. Correct angle and radius of dovetail cut

Correct:

Dovetail is cut to 60 degrees with an interior radius matching dovetail preparation specs for your product. Dovetail gauge should fit perfectly.

Incorrect:

Angle or interior radius is incorrect. May indicate cutter needs to be replaced.

5. Locating pin slots precise and accurate

Correct:

Locating pin slots are accurately placed and cut with straight walls following exact measurements found in dovetail preparation specs.

Incorrect:

Locating pin slots are in wrong location or have tapered walls harming repeatability of part.

Email Newsletter

Be the first to receive the latest news and exclusive offers via our newsletter.

Alexia House, Glenmore Business Park

PO19 7BJ Chichester

United Kingdom

0333 207 4497

sales@wixroyd.com

Route via Google Maps

Company registration no: 00496138

Company VAT number GB 408154022