Captive Screws from Wixroyd

What is...

A Captive Screw is a fastener specially designed to remain in place within an assembly when the assembly is removed. They achieve this by having the threaded section a larger diameter than the main length of the screw. Their primary use is for guard panels and safety guards to comply with EU Machine Safety Directive 2006/42/EC, which requires fasteners remain attached to fixed guards or equipment when guards are removed.

Wixroyd Captive Screws are manufactured mainly from stainless steel (A2) but are also available in aluminium, brass or zinc plated steel. Our technical support team can help provide you with assistance on making sure your application complies with the EU safety directive or general technical help on their use.

Threaded captive washers for use with our captive screws, available in stainless steel (A2, AISI 303 and A4, AISI 316) and zinc plated steel.

Stainless Retainer Flanges for retaining captive screws in a panel.

Associated Products

Pan Head Integral Sealing Screws feature an O-ring underneath the screw to provide bi-direction sealing. This makes them ideal for protection against contaminates such as a dirt.

Button Head Integral Sealing Screws feature an O-ring underneath the screw to provide bi-direction sealing. This makes them ideal for protection against contaminates.

General Guidance

One option to retain screws to panels are our Retaining Washers. Used in place of Retainer Flanges, Retaining Washers are simple but effective when used with our Captive Screws. The Captive Screws have a normal thread and a reduced diameter for the rest of the screw length.

The Retaining Washer has a small length of thread on the internal diameter and once screwed on to the Captive Screw is effectively captive.

Preparation

- Selection retainer based upon panel thickness

- Countersink panel

Applications

Screw the thin Retaining Washer onto the Captive Screw and the screw is therefore retained to the panel.

Materials

Coatings

Many finishes can be applied - black oxide finish, anodizing etc.

The main options are as follows:

| Finish | Notes |

| Black Chrome (MIL-C-1458B) | Black chrome is hard, non-reflective coating which is resistant to abrasion, heat and erosion. The black chrome surface is a dull, dark grey and may be waxed or oiled to darken surface. |

| Black Oxide Coating (MIL-C-13924B) | Black oxide is a uniform black coating for ferrous metals. Generally it is considered a decorative coating and provides only very limited corrosion protections under mild corrosion conditions. |

| Cadmium | Cadmium is a bright, silvery white plating. Supplementary treatments for type II can be golden, iridescent, amber, black or olive drab. |

| Passivate (QQ-P-35/MIL S-5OOSC) | Passivation is a process designed to remove foreign metals from the surface of stainless and corrosion resistant steels. |

| Phosphate Coating Ligth (TT-C-0D490B) | Phosphate coating is a light coating for use as a base paint. |

| Gold (MIL-G-45204B) | Yellow to orange colour depending on a proprietary process used. Will range from matt to bright finish depending on base metal. Good corrosion resistance and high tarnish resistance. |

| Nickel | Nickel is a corrosion protective plating for steel, zinc and zinc alloys as well as copper and copper alloys. |

| Zinc (QQ-Z-325C) | The primary use of chromate finishes on zinc is to retard or prevent formation of white corrosion products on zinc surfaces. |

| Schematic | Drive Types | Uses |

| Hexagonal recess | Ideal for precision assembly. Most recommended where less surface area is available. |

| Crosshead (Phillips®) | Provides good control in driving. Always use a driver bit of the proper size which is in good condition. |

| Star Head (Torx®) | Positive-engaging, fast-locating method which transmits drive torque with less required downward pressure. Good fastening appearance. |

| Slotted | Accepts standard blade screwdriver. Requires less downward pressure to drive parts than those with recessed openings. Use a proper fitting blade to minimise slippage. |

| Security | These screws are impossible to remove without the special matching screw driver. |

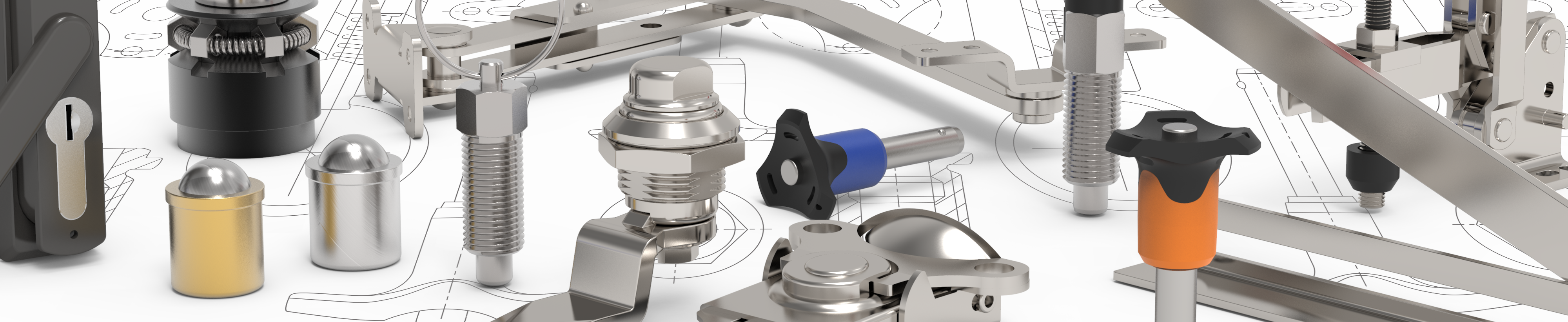

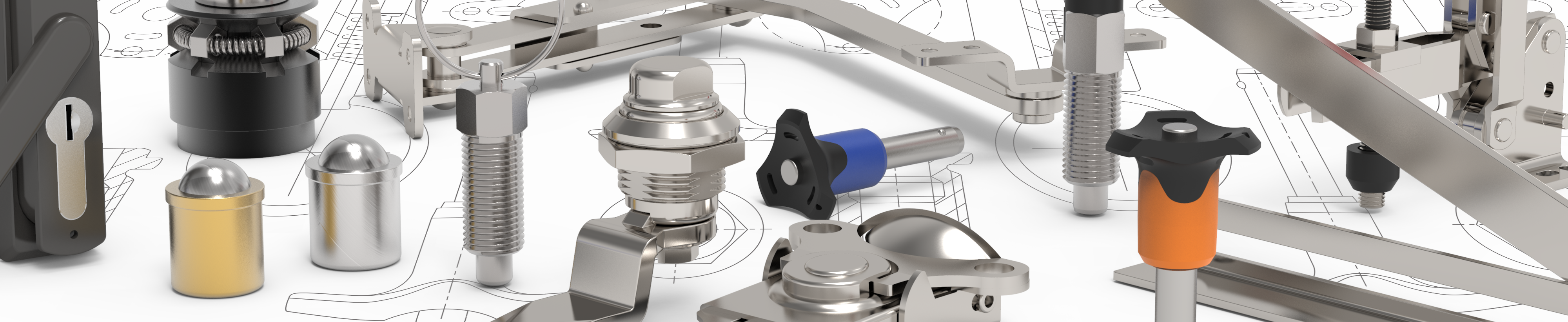

Request A Free Catalogue Today!

Explore a huge range of components from Spring Plungers to Clamping Systems with our free Design Elements, Access Components and Workholding catalogues.

Email Newsletter

Be the first to receive the latest news and exclusive offers via our newsletter.

Alexia House, Glenmore Business Park

PO19 7BJ Chichester

United Kingdom

0333 207 4497

sales@wixroyd.com

Route via Google Maps

Company registration no: 00496138

Company VAT number GB 408154022