Clamping and Workholding from Wixroyd

What is...

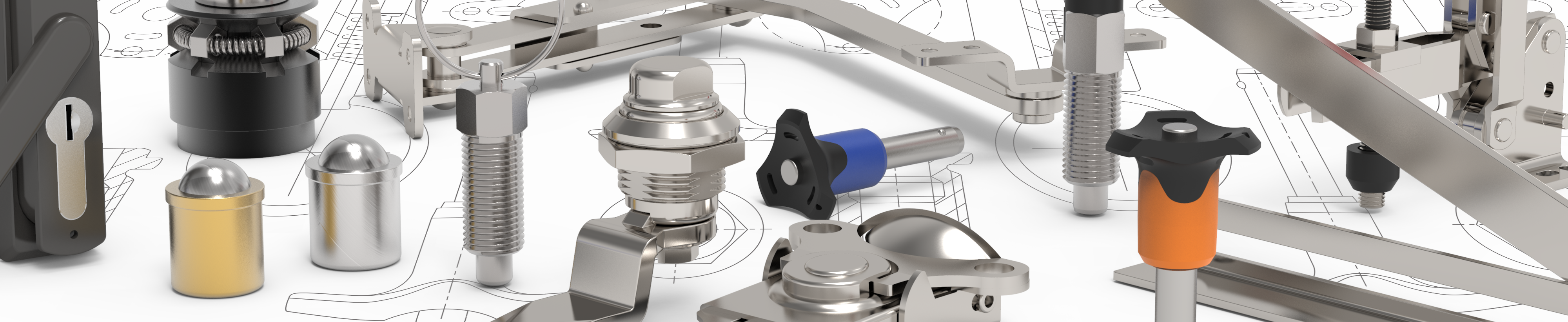

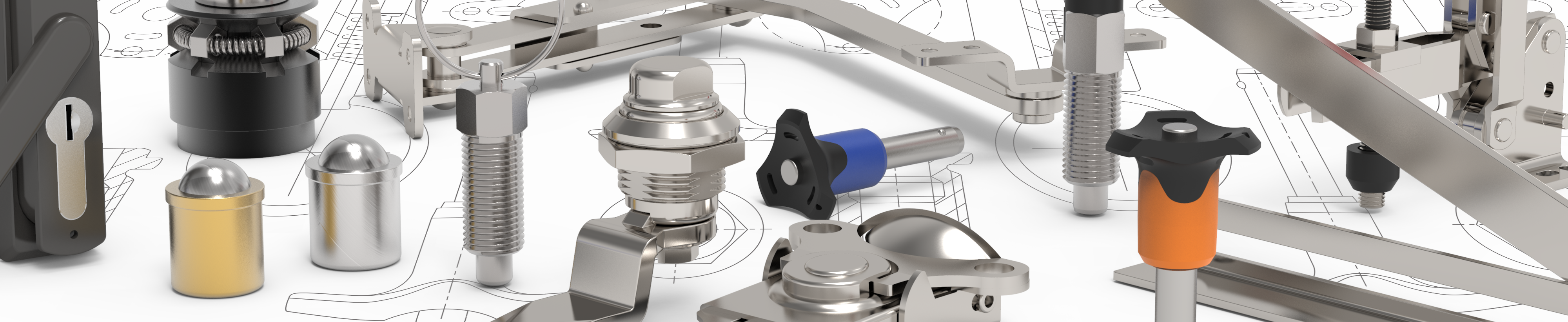

Wixroyd's comprehensive range of machine elements, standard parts, access components and workholding equipment contains a broad selection of sizes in materials including; stainless steel, steel, die-cast zinc as well as plastic. CAD models of Wixroyd components are available for free visit CAD download. For a free copy of the latest Wixroyd catalogue, the designers indispensable guide to A Range of Endless Possibilities, visit free literature.

Wixroyd are trusted by some of the best known design and manufacturing companies - helping them design, manufacture and assemble their products. Let our technical engineers help solve your unique application challenge.

A comprehensive range of low profile clamps that are suitable for low-height components. Pitbull Clamps provide clamping by positive down-force.

T-Slot Clamps have a clamping point 5mm above the machine table. Risers may be used to allow for through machining/drilling. With a clamping range of 1,2mm and torque 9 Nm.

Fixture Clamps are used to hold irregular or round parts for machining. They come with a mild steel washer that can easily be machined to match the profile of the component.

Traditional manual workholding clamps with excellent durability; plain, stepless, goose neck and finger clamps for the machine table to suit most T-slot table sizes.

Holds two workpieces with equal force. Very effective for multiple workpiece clamping. Can easily be used with hydraulic pull cylinders.

The more traditional type of clamps for manual workholding solutions with a varied range. Some of the range include; plain clamps, forked clamps and fingers clamps.

Our Chain Clamping Sets are available in two sizes for large diameter work pieces as well as for use on fixture sub-plates and machine tables.

Our range of heavy-duty side clamps are very powerful, compact and offer up to 2.2 tons of clamping force. 2.2 ton clamps have a low height, with a very powerful compact clamp. When used in conjunction with fixed stops, these clamps achieve a positive downforce on both faces of the workpiece.

Centre acting Cam Clamps and Eccentric Clamps for the quick and easy holding of parts during light machining or assembly.

With or without seal; threaded and non-threaded versions also available. Pin comes in zinc-coated case-hardened steel or plastic (POM - polyoxymethylene). Different spring forces available within the range.

Vacuum Clamping Systems available from Wixroyd - excellent for holding wood, plastics, aluminium and other non-ferrous metals, which require quick and simple machining. Minimises likelihood of damage to the workpiece. Quick, simple and cost-effective means to reduce change-over time.

Our Horizontal Acting Toggle Clamps made from zinc-plated and passivated steel or in stainless steel. Bushes are case hardened and greased. Handles are made from oil resistant plastic to ensure easy operation.

Our range of Vertical Acting Toggle Clamps made from zinc-plated and passivated steel or in stainless steel. Bushes are case hardened and greased. Handles are made from oil resistant plastic to ensure easy operation.

Our range of Push-Pull Toggle Clamps for space efficient clamping at low workpiece heights. Stainless versions are also available.

Associated Products

Wixroyd offers two types of T-Slot Bolts one in strength class 8,8/10 and the extra strength version in 12,9 class steel.

Steel strength class 10, heat-treated steel T-Nuts made to DIN 508. Free CAD models are available for our T-Nut products.

Steel strength class 10, heat treated Fixture Nuts made to DIN 508. Free CAD models are available for our Fixture Nut products.

Tempered steel Dished Washers made to DIN 6319G. Punched, trued and tempered. Larger diameter makes them suitable for bridging clamp slots.

Made from carbon steel. These Screw Jacks have a centering hole of ∅12mm.

Universal Step Blocks made from enamelled, heat treated steel. Can be used in pairs for all clamps or individually with clamps such as our 10020 products.

Self Aligning Pads can be used to act as stops, supports and thrust elements. This particular range comes in steel with a longer thread and lock nut to make it adjustable in height to suit your application.

Features

Used in our clamps:

10940.W0210,

10880.W0105,

10920.W0125,

11040.W0025,

11041.W0080,

11042.W0027,

11043.W0081,

11070.W0020,

11071.W0080,

11080.W0610 to 11083.

Our Horizontal Clamps have a unique "three finger" arrangement, ensuring components are both pulled down and clamped in the same motion. The face of the clamp is made of three parts or fingers:

- Two outer flexible fingers 1; for pulling down the component to the work table.

- One solid central finger 2, or clamping stop; to provide side clamping.

Available in two styles: smooth and serrated face. They can also cater for workpieces with an adverse angle on the clamping face; for example flame cut steel blanks.

General Guidance

Clamping action

Contact

The clamp's outer flexible fingers 1, are approximately 0,254mm longer than the solid central finger/clamping stop 2. This slight difference in length means it is the flexible fingers that first come into contact with the workpiece.

As initial contact is made with the workpiece, the flexible fingers 1 apply downward pressure forcing the workpiece down against the work table. The flexible fingers are compressed until they are the same length as the solid central finger/clamping stop 2.

Clamping

As the solid central finger/clamping stop 2 comes into contact with the workpiece, it applies high side clamping pressure to achieve clamping forces up to 2,2 tons (dependent upon clamping model selected).

Machining

During machining, the uniquely designed flexible fingers 1 continue to flex and twist, applying downward pressure to keep the workpiece flat to the work table throughout.

Request A Free Catalogue Today!

Explore a huge range of components from Spring Plungers to Clamping Systems with our free Design Elements, Access Components and Workholding catalogues.

Email Newsletter

Be the first to receive the latest news and exclusive offers via our newsletter.

Alexia House, Glenmore Business Park

PO19 7BJ Chichester

United Kingdom

0333 207 4497

sales@wixroyd.com

Route via Google Maps

Company registration no: 00496138

Company VAT number GB 408154022