Universal Joints From Wixroyd

What are Universal Joints?

Universal Joints are coupling joints designed to connect shafts whilst allowing for free movement and flexibility. This allows angle discrepancies between the two connecting shafts whilst allowing for efficient torque transmission, meaning for example they are suitable for use in drive shafts for machinery.

Wixroyd’s range of Universal Joints come bored and unbored, with plain or needle roller bearing variants, but we are also able to provide square and hex bore variations on request. For further assistance or requests don’t hesitate to get in touch with our technical support team who will be happy to deliver the best solution for your application.

Steel Universal Joints are used where shafts off-set towards each other. Manufactured to DIN 808/7551. Maximum bending angle of 45° per joint.

Steel single Universal Joints manufactured to DIN 808. Maximum bending angle of 45° per joint. With round bore or with keyway.

Stainless steel single Universal Joints manufactured to DIN 808. Maximum bending angle of 45° per joint.

Steel double Universal Joints manufactured to DIN 808/7551. Maximum bending angle of 45° per joint.

Steel double Universal Joints manufactured to DIN 808. Maximum bending angle of 45° per joint.

Stainless steel double universal joints manufactured to DIN 808. Maximum bending angle of 45° per joint.

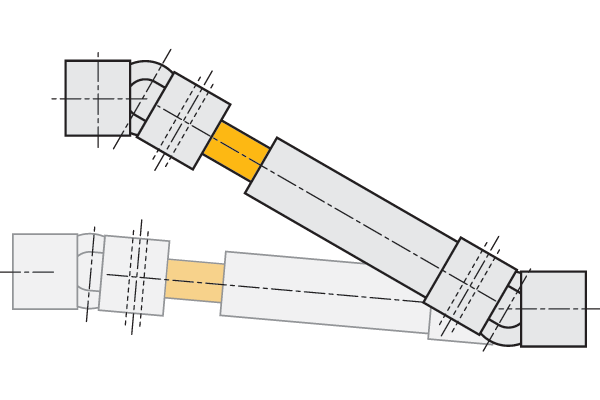

Steel telescopic Universal Joints manufactured to DIN 808. Keyway both ends. Maximum bending angle of 45° per joint.

Bellows for single and double Universal Joints. Made from black elastomer plastic. Gives Universal Joints full protections against ingress of dirt.

Associated Products

Quick Plug Couplings made from heat treated steel. For quick coupling/uncoupling of components within linear movement applications.

Cam Locking Quick Plug Couplings, actuated via 90° turn. Suitable for use in pneumatic and hydraulic lifting cylinders.

Features

Overview

Single Universal Joint

Available with plain bearings or needle roller bearings. Plain bore and keyed bores stocked as standard; hex or square shaped bores on request. Bore diameters 6mm up to 50mm.

Stainless Steel Universal Joints

Single and double Universal Joints with plain bearings and plain bores. Keyed or hex or square shaped bores available on request. Bore diameter 6mm up to 30mm.

Double Universal Joints

Available with plain bearings or needle roller bearings. Plain bore and keyed bores stocked as standard: hex or square shaped bores on request. Bore diameters 6mm up to 50mm.

Quick Release Universal Joints

Quick charge mechanism on one end of the joint to allows rapid connection and release of the shaft; ideal when time is critical. Bore diameters 8mm up to 30mm.

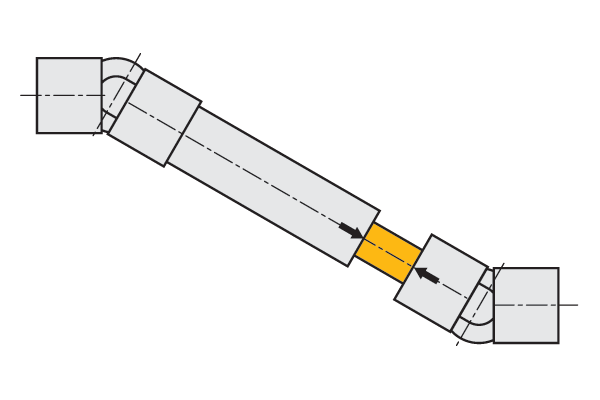

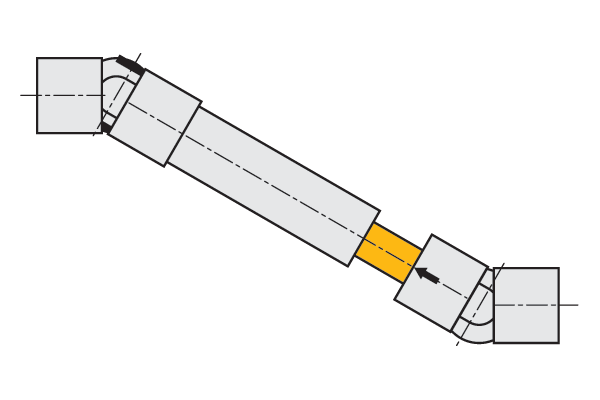

Telescopic Universal Joints

Two Universal Joints connected by a sliding splined shaft with the ability to extend, allowing adjustments in length during installation. Bore diameters 10mm up to 30mm.

Universal Joint Bellows

Available for both single and double Universal Joints, bellows are used to cover and protect the joints. Available to protect joints up to 58mm outside diameter.

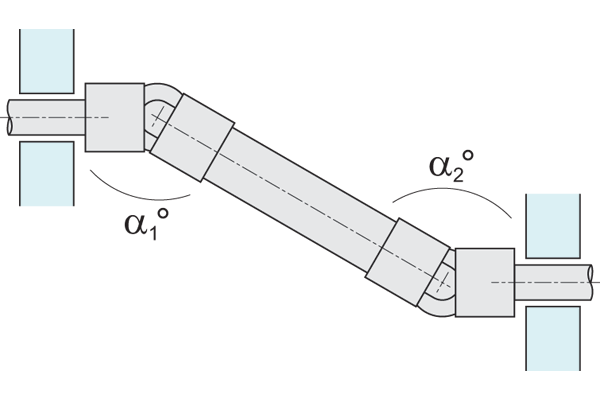

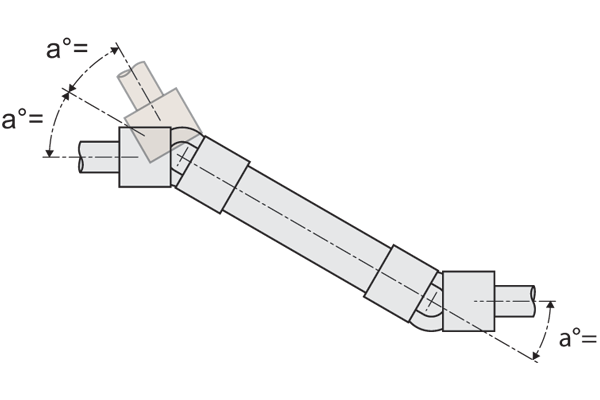

When one single joint is coupled with two shafts (of which the driving one is rotating at a constant speed) forming an angle, a periodic variation of the driven shaft is caused with exactly four fluctuations per revolution.

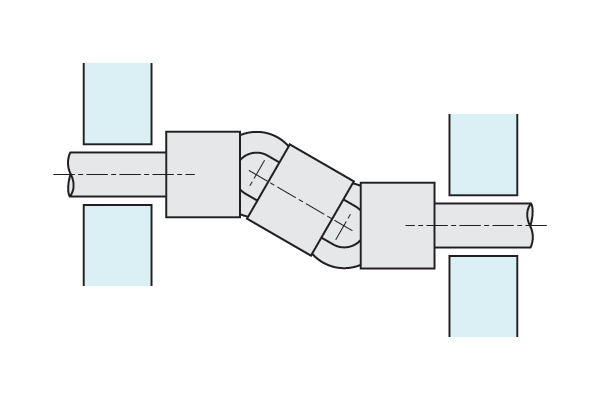

The difference between the maximum and the minimum speed of the driven shaft depends on the angle formed by the two shafts. The difference grows with an increase of the angle a°. To have homokinetic transmission, either two opposite single joints (ensuring that the two central yokes lie on the same plane and the angles are equal) or double joints need to be fitted. The irregularity caused by the former articulation is cancelled by the latter. The overall length resulting from the coupling of the two single joints can be reduced by using a double joint. In other words, the double joint is to be considered as the shortest homokinetic transmission.

For low speed applications (Max. 1000 rpm), joints with plain bearings (rubbing bearings) are suggested. They are able to support shock loads, motion reversals, irregular runnings and relatively high torques. The working angles must be restricted when using at speeds between 500 - 1000 rpm. Please consult our technical department if you have such an application.

For high rotation speeds, relatively low torques or wide angles, joints with needle roller bearings are preferred. They can reach 4000 rpm dependent on the angle.

Installation

Dynamic basic load ratings of Plain Bearing Rod Ends

To obtain a uniform rotary motion, always use either two opposite single joints or one double joint a1 = a2.

The pillow blocks supports should be positioned as close as possible to the joints.

When using two opposite single joints, ensure the alignment of the inside yokes.

In extensible transmissions, make sure that the arrows are perfectly aligned.

It is essential that the two bending angles a° are equal.

Request A Free Catalogue Today!

Explore a huge range of components from Spring Plungers to Clamping Systems with our free Design Elements, Access Components and Workholding catalogues.

Require Technical Help?

Do you require technical help? Please enter your details below and we will contact you as soon as possible

Email Newsletter

Be the first to receive the latest news and exclusive offers via our newsletter.

Alexia House, Glenmore Business Park

PO19 7BJ Chichester

United Kingdom

0333 207 4497

sales@wixroyd.com

Route via Google Maps

Company registration no: 00496138

Company VAT number GB 408154022