Vacmagic From Wixroyd

What is...

Wixroyd's comprehensive range of machine elements, standard parts, access components and workholding equipment contains a broad selection of sizes in materials including; stainless steel, steel, die-cast zinc as well as plastic. CAD models of Wixroyd components are available for free visit CAD download. For a free copy of the latest Wixroyd catalogue, the designers indispensable guide to A Range of Endless Possibilities, visit free literature.

Wixroyd are trusted by some of the best known design and manufacturing companies - helping them design, manufacture and assemble their products. Let our technical engineers help solve your unique application challenge.

- Pallets can be swapped in 30 seconds or less.

- Load pallets while machining to maximise productivity.

- Base receiver dimensions size 315mm x 140mm.

- Pallets can be swapped in 30 seconds or less.

- Load pallets while machining to maximise productivity.

- Base receiver dimensions size 323mm x 330mm.

- 4 Vacuum ports to allow 1-4 small parts or a larger part.

- Grid plate tapped with M6 holes to allow extra clamps and stops.

- Base receiver dimensions are 406mm x 355mm.

This video is disabled because of your cookie settings.

General Guidance

Why choose a Vacuum System?

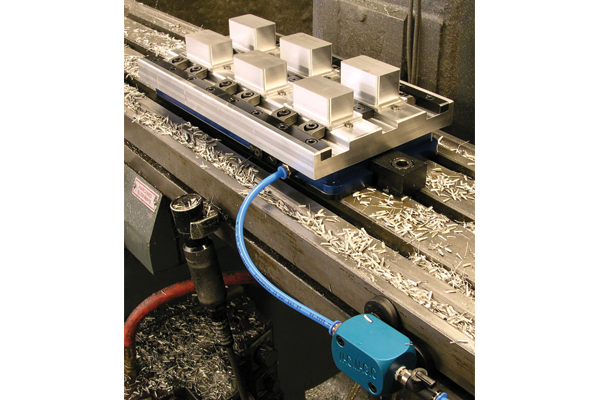

Compatible with CNC machines; Vacuum Clamping is cost-effective, increases productivity and minimises any clamping damage to the workpiece.

The VacMagic system enables high volume production runs at the same feeds and speed as traditional pallet systems, with less set up time and hence reduces spindle idle time.

The low profile base unit of the VacMagic can be used either as a vacuum pallet or a standard pallet, set up as a fixture plate, for increased productivity. Alternatively a standard vice can be mounted directly onto the VacMagic base for easy loading and unloading, eliminating the need to index the vice on each use – providing quick change over from prototype to production volumes.

Multi-Power Vac has a 400mm x 350mm grid plate base, tapped with M6 threads and a finely textured surface increasing holding force through friction. It offers greater flexibility for multiple workholding solutions.

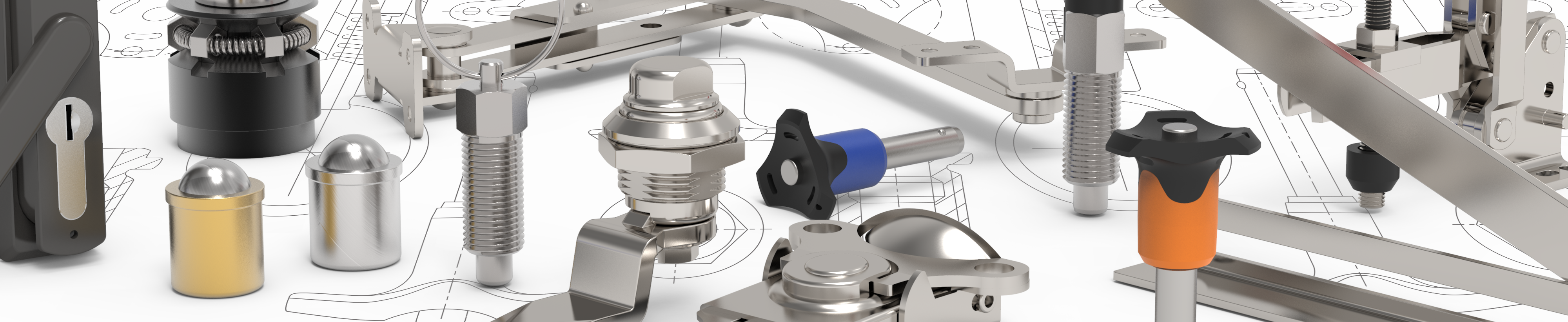

What is the basic principle of Vacuum Clamping?

When a vacuum is created, a pressure differential is created between the Vacuum Clamping plate and the workpiece. The vacuum causes an ‘underpressure’ beneath the workpiece which effectively presses the workpiece against the clamping plate, thus the workpiece is not ‘sucked’ but rather ‘pressed’ against the vacuum table.

The sliding force of the workpiece depends on its surface structure, the pressure differential generated by the vacuum and the workpiece area on which the vacuum acts. The larger the area, the better the holding force.

What is a vacuum?

A vacuum is the state in a space which is free of matter. In practice, we refer to a vacuum when the air pressure in a space is less than that of the atmosphere.

Why does a vacuum generate a holding force?

All objects are subject to atmospheric pressure of approx. 1 bar. When a vacuum is generated some of the air under a workpiece is removed, thus removing part of the pressure load on the workpiece surface.

The net result is a one-sided pressure on the top surface of the workpiece, the strength of this one-sided pressure is dependent upon the size of the vacuum generated – generally this is 0,7 to 0,8 bar. This means that a vacuum of 200mbar (absolute pressure) is generated, and hence the pressure differential acting on the workpieces is 800mbar (approx. 0,8kp/cm). Size of the clamping force is then only dependent on the clamping area.

Formulae to calculate clamping force generated by a vacuum

Force = pressure x area

F (N) = bar x A (m2) x 105

1 bar = 10N/cm2

Typical units of measure:

100 Pa = 1 hPa

1 hPa = 1 mbar

1 mbar = 0,001 bar

Features

What materials can my Vacuum System work with?

The Vacuum System is ideally suited for difficult to hold parts, parts too thin for traditional workholding, as well as soft or brittle materials such as graphite and plastics. It is an ideal alternative to the magnetic chuck for non-magnetic material such as wood or plastic.

Applications

More than just a Vacuum System, it is a fully flexible damping and fixturing solution.

Mount the base unit to the grid plate, T-slot table or in a vice.

Make your own vacuum fixtures for fully flexible fixturing.

Will accept the standard SL0430.45150 pallet, increasing your vacuum platform to over 360 x 315mm.

Sliding stop SL0490 used to assist in low profile positioning on our Vacuum System.

Applications

Application 1

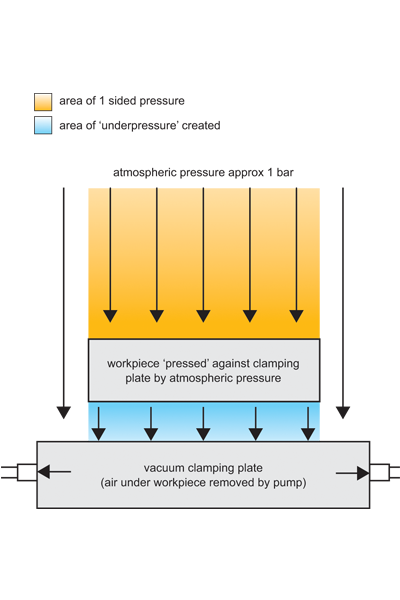

1. A custom “sacrificial plate” was made to cover the multi-power Vacuum Clamping plate for machining of thin and delicate parts.

2. Sacrificial plate is easily secured to multi-power Vacuum Clamping plate via four flat head screws.

3. To maximise the flexibility of the machining process, four multi-power Vacuum Clamping plates have been connected together and are run from one standalone vacuum pump. Here three very different components are being held; one long workpiece even stretches across two vacuum units.

Application 2

4. Multi-power Vacuum Clamping plates are suitable for large and small components. In this application, six units have been connected together to achieve a very large clamping area of approx. 1200 x 700 mm.

5. To hold delicate components, a customer pallet has been designed; vacuum ports were accessed through the pallet with a grid pattern to suit the component. Grid is sealed using supplied vacuum gasket to create vacuum seal.

6. Workpieces are aligned to the vacuum seal and loaded. Air supply is initiated and workpieces are clamped ready for machining.

Email Newsletter

Be the first to receive the latest news and exclusive offers via our newsletter.

Alexia House, Glenmore Business Park

PO19 7BJ Chichester

United Kingdom

0333 207 4497

sales@wixroyd.com

Route via Google Maps

Company registration no: 00496138

Company VAT number GB 408154022