Wixroyd Shock Absorbers 68001 - 68032

What is...

Shock Absorbers are widely used in industries where the speed, direction or movement of objects must be changed or stopped. Without suitable methods of control the kinetic energy inherent in many moving objects, which occur in manufacturing, can result in increased machine wear and even machine damage.

Ideally any method of "shock absorption" should provide two key features;

1) Bring the moving object to rest quickly, smoothly and without rebounding forces

2) In-built reliability and safety

Shock Absorbers are able to quickly convert the kinetic energy of a moving object into heat and dissipate this into the air. They are also able to provide a constant linear deceleration of an object throughout its entire impact stroke to quickly, smoothly and quietly bring a moving object to rest, with the lowest reaction force and in the shortest time. All of these features mean increased manufacturing productivity, extended machine life, and improved efficiency.

General Guidance

The cost of outdated buffering methods

Traditional buffering methods:

- Springs

- Dash Pots

- Air Buffers

- Rubber bumpers.

Costs associated with outdated cushioning methods:

- Loss of production

- Increased machine wear and tear

- Increased maintenance cost

- Increased vibration and noise pollution

- Varying and inconsistent dampening forces, with non-linear or high peak forces at some point in their stroke.

Traditional buffering methods can only dissipate a small percentage of the kinetic energy of a moving object. The remainder is stored (rather than dissipated) as elastic energy which results in high resistance and rebounding forces toward the end of the impact stroke.

Benefits of using Wixroyd Shock Absorbers

Wixroyd Shock Absorbers are designed to stop a moving object smoothly and quietly from the beginning to the end of its impact stroke. Their design enables a constant resistance force or linear deceleration throughout the impact stroke, quickly converting the kinetic energy of the moving object into heat, which is quickly dissipated into the air. A linear deceleration curve, as achieved by our Shock Absorbers, brings an object to rest in the shortest time while reducing damaging impact forces.

Energy Capacity: Shock Absorbers can absorb more energy, without increasing deceleration or reaction forces.

Stopping Force: Shock Absorbers provide smooth decelaration of parts, which means less machine wear and hense reduced maintenance.

Stopping Time: Shock Absorbers bring moving loads to rest more quickly, increasing productivity.

Advantages of using Wixroyd Shock Absorbers

- Consistent and reliable dampening force or linear deceleration, throughout entire impact stroke

- Smoother motion and deceleration of moving parts

- Increased productivity

- Extended machine life and improved efficiency

- Improved health and safety, through reduced vibration and noise pollution

Advantages of using Wixroyd Shock Absorbers

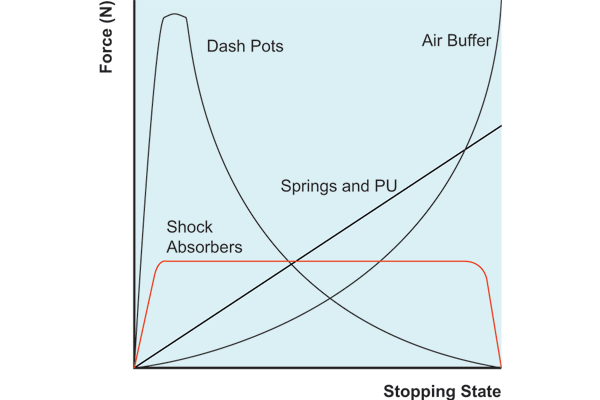

Dashpots: Produce large peak forces at beginning of impact stroke, abruptly slowing load - however braking force quickly declines.

Springs & Rubber Buffers: Energy is stored rather than dissipated, resulting in rebounding of the load.

Air Buffers: Initial braking force is low, but due to the compressibility of air, it increases sharply toward later stages of stroke, resulting in inconsistent braking force.

Shock Absorbers Designed to stop a moving object smoothly and quietly from beginning to end of its impact stoke. Their design enables constant resistance force or linear deceleration throughout impact stroke, they quickly convert kinetic energy of a moving object into heat which is quickly dissipated into air.

Features

Wixroyd Shock Absorbers are available in two primary types:

Self-compensating

Self-compensating Shock Absorber 68001

Our Self-compensating Shock Absorbers are effective for a stated range of Effective Mass (Me), and are self-compensating within this range (see selection charts). As long as the applications effective mass remains within the given range, then no additional adjustment is required for changes in weight, speed or propelling force.

See models: 68001, 68002, 68003, 68004, 68008, 68012

Self-compensating Shock Absorber 68002

Each Self-Compensating Shock Absorber is available in three standard max. impact speed (v-m/s) variations:

1 - high impact speed

2 - medium impact speed

3 - low impact speed

For specific max. impact speed values please refer to the selections charts and the specific product tables.

For hard impact, at the start of a stroke, it is advisable to choose a high impact speed model. For hard set down, at the end of a stroke, it is advisable to choose a medium or low impact speed model, or to move up to the next higher bore size.

Adjustable

Adjustable Shock Absorber 68020

Set collar to 0 at initial installation

After a few cycles, adjust collar setting to suit application

Adjustable Shock Absorbers have an adjustment collar at their base (with a scale of 0-9), which enables adjustment of the Shock Absorber's optimum deceleration to suit the application.

After initial installation, the Shock Absorber should be cycled a number of times to settle and then the adjustable collar turned to the desired position for the application.

Stop collars

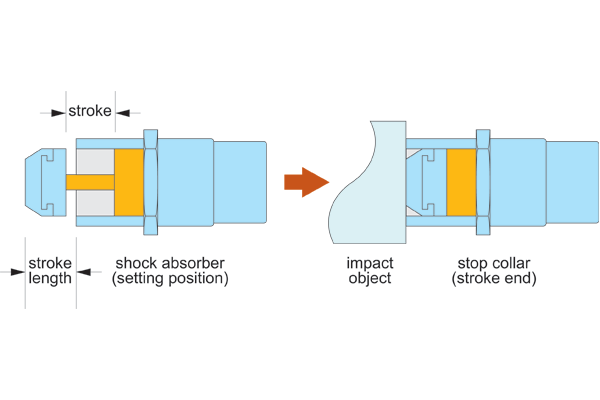

We advise the use of external mechanical stops with all of our Shock Absorbers, typically within 1 to 0.5 mm from the end of the stroke. Alternatively, we have a range of stop collars available, which can be mounted directly to the Shock Absorber body (see our part 68030). Stop collars are available for our M8 to M36 threaded models, they can be used both to adjust stroke and also to fix the end position of the load.

Flange Mounting Adaptors

Basic mounting of Shock Absorbers is through the use of its threaded body and lock nuts supplied. Alternatively, Shock Absorbers can be flange mounted. Please see our available flange mounting adaptors; part 68032 for our M36 and M42 threaded models.

Muffler Caps

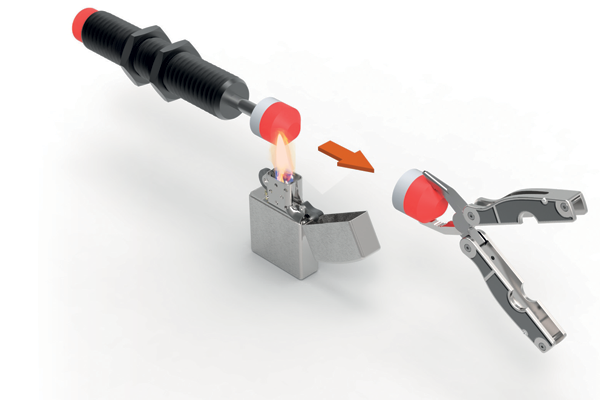

Shock Absorbers are supplied with muffler caps as standard. Muffler caps can be removed from the Shock Absorber Piston by heating them with a lighter and pulling away using a pair of plyers.

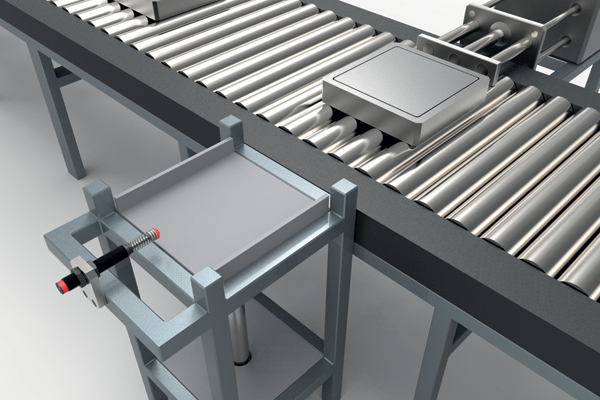

Applications

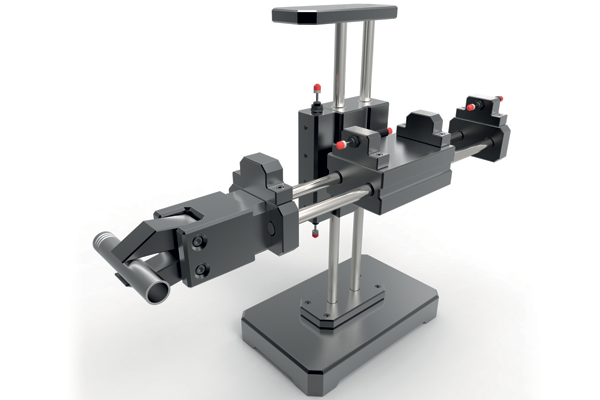

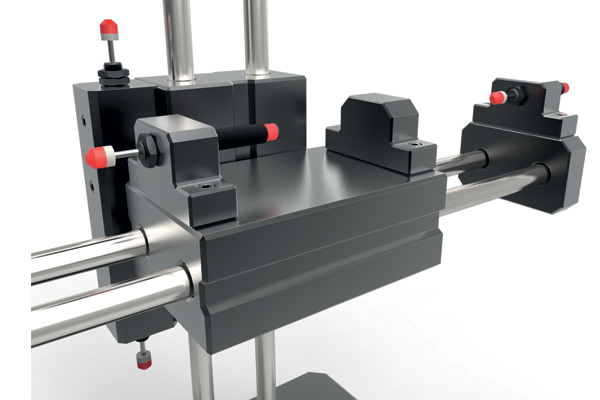

Pick and place robots

Pick and place machines

Technical Specs

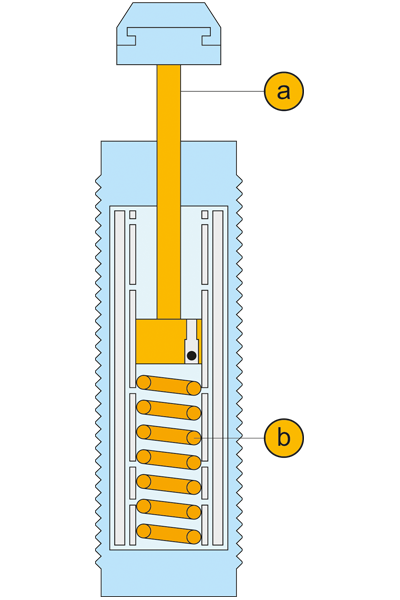

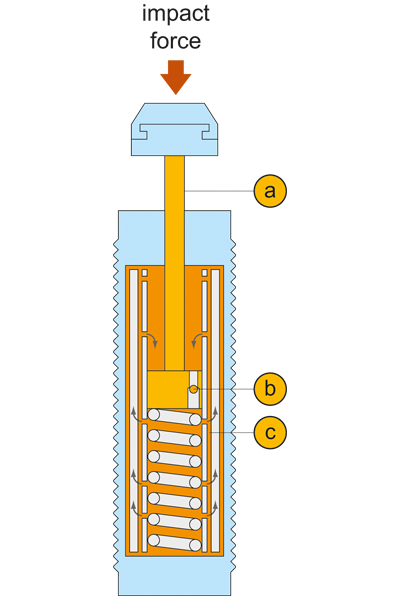

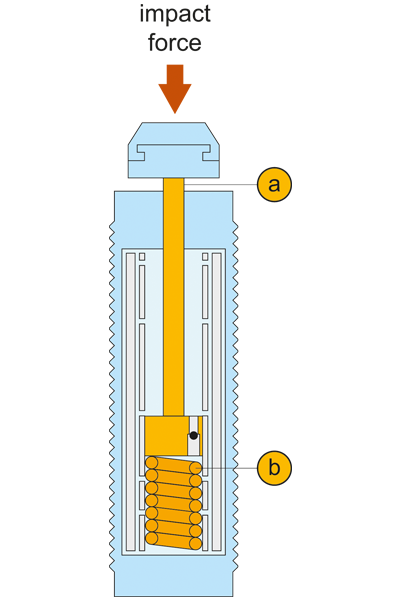

At rest

1) Shock Absorber at rest, piston rod A, fully extended through force exerted on it by return spring B.

Initial Impact

2) Moving load impacts piston A, which moves into Shock Absorber body increasing pressure in chamber.

3) Piston rod check valve closes B. Hydraulic oil behind the piston head is initially able to escape/vent into the accumulator.

Continued impact and linear decelaration

4) As load on piston rod A increases, the rod continues to move back into the inner tube, as it does so the number of available metering orifices B through which the hydraulic oil is able to escape reduces; hence the velocity of the moving load continues to decelerate.

5) The number and position of the orifcies are such that the pressure in the inner tube remains constant throughout the entire impact stroke, providing constant linear decelaration. (Number of metering orifices decreases proportionally through length of piston rod).

Initial Impact

6) The moving load is brought to a smooth and quiet stop.

7) When the load is removed, the return spring B pushes the piston A back to its original resting position, ready for the next cycle.

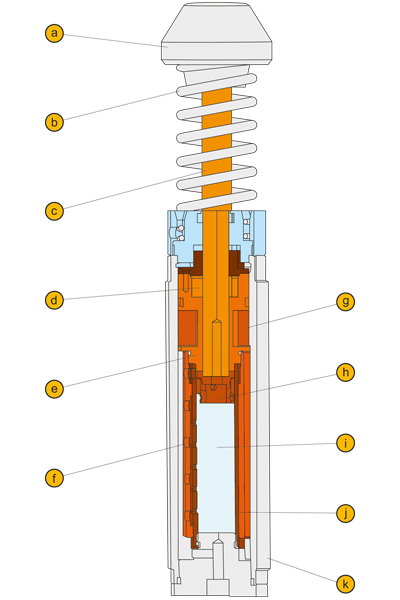

Shock Absorber Design

The design of Wixroyd Shock Absorbers is beautifully simple and effective. Made from high quality marterials and components, they provide the highest performance and reliability.

a - Impact Cap

b - Return Spring; DIN GWP (external and internal models avai.)

c - Piston Rod; AISI 1045, hardened to HV940°, chrome plated

d - Seal

e - Bearing

f - Orifices

g - Accumulator; neoprene rubber

h - Check Valve

i - Fluid

j - Inner Tube

k - Outer Tube; STKM11A, hardened and blackened

Alexia House, Glenmore Business Park

PO19 7BJ Chichester

United Kingdom

0333 207 4497

sales@wixroyd.com

Route via Google Maps

Company registration no: 00496138

Company VAT number GB 408154022