Cam Latches with Handle from Wixroyd

What is...

The Cam Latch is a simple locking mechanism used to achieve the securing of access to panels and entry points. They are comprised of a body and latch which rotates when actuated to secure or release. Cam Latches with Handles provide better grip for this function and are also available with compression lock versions, for extra sealing to help reduce vibration. Notable uses include equipment cabinets, enclosure doors, machine access panels and tool lockers.

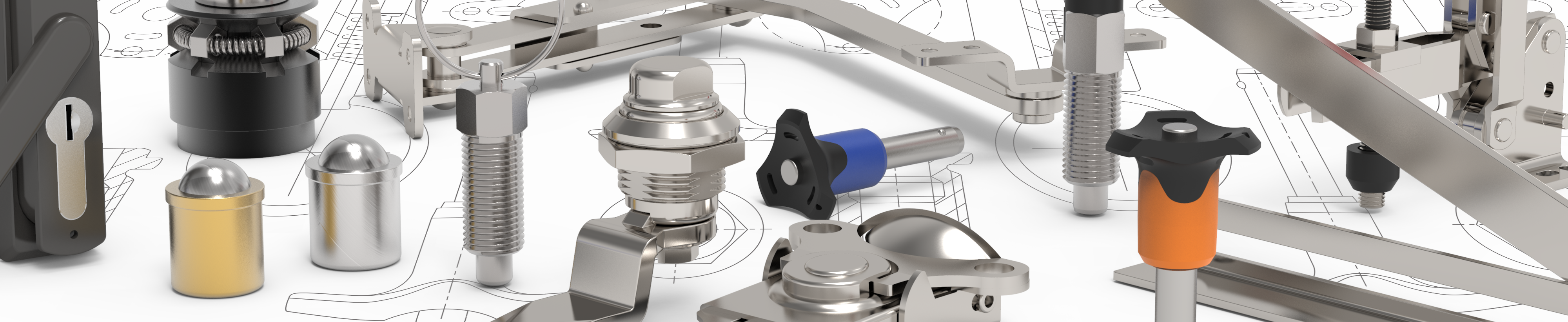

All our Flexi-system Cam Latches use a standard cut out dimension of 22.2 Ø and 20.2 square which accommodates many industry standards. Available in die cast zinc, stainless steel and plastic. Cam and Key are sold separately. For assistance with choosing the right cam off-set for your application, please refer to the datasheets provided or get in touch with our technical support team.

Black Plastic Wing Handle, with choice of finish on zinc body. Wing handle acts as handle and lock actuator.

Finger Handle Cam Latch. Locks with quarter-turn of the handle. Available with zinc or plastic handle.

Star Grip Handle version of our cam latch, available in zinc or polyamide. Suitable for panel thicknesses of 1-6mm.

Padlock Wing Handle Locks with quarter-turn. Design accomodates two different padlock sizes. Black coated or Chrome finish.

Compression Locks provide sealing of enclosures to reduce vibration and to provide noise isolation. Adjustable grip type has an extended stem which can be cut in length to best suit your application.

T-handle Cam Lock. Available in Keyed alike and Keyed to differ. Chrome or black coated.

T-handle Cam Latch. No lock for easy actuation. Body lengths from 18 to 62mm. Suitable for thicker doors.

L-handle Cam Lock. Keyed alike, Keyed to Differ and Euro Key options, as well as blank, no lock version. Chrome, plastic or black.

Padlock attachment L-handle Cam Lock. Handle style. Chrome of black coated. Quarter-turn action.

Associated Products

Standard gaskets made from EPDM rubber, suitable for industrial use. Supplied in 10m lengths as standard. Larger lengths in multiples of 10m are available on request.

For plain/flush mounted doors, as well as electrical panels and covers. Made from die-cast zinc with black powder coat.

FAQs

When selecting a Wixroyd Cam Latch for your application, you need to answer these questions:

1. Which installation cut out?

2. Which body style?

3. Which locking key?

4. Which accessories?

5. Which cam type and size?

Step 1: Which installation cut out?

Cut Out

All our Flexi-System Cam Latches use a standard installation cut out 22,2 dia, 20,2 square, for maximum flexibility. We also provide a number of alternative cut out dimensions for legacy/historical installations.

Step 3: Which locking key?

Standrad insert driver keys

Our range of Insert Driver Cam Latches require a simple key to actuate. Refer to part A0102 and A0103 for correct keys.

Cylinder Locking

Our Cam Locks with Cylinder Locks are supplied with two keys per lock. Available as Euro key 5333, keyed alike or keyed to differ locks.

Step 2: Which body style?

Material and finish

Select from our variety of die-cast zinc, polyamide plastic and stainless versions.

Actuation and locking method

Standard insert driver type, cylinder lock or wing handle type.

Number of latching points in application

Typically, Single Point Latching is required, but the Wixroyd Flexi-System also provides Multi-point Latching (typically 3 point - at lock point, top and bottom of cabinet).

Step 4: Which accessories?

- Multi Point latching: use our rod set A0303 or A0325 for suitable rods and rod guides.

- Finger Pulls: easily installed with any of our flexi-system cam bodies, finger pull no. A0352 is a simple, cost effective handle for your cabinets.

- Dust cap: to reduce material ingress.

Step 5: Which cam type and size?

Wixroyd Cams are available in a number of different materials; zinc plated steel, stainless steel (AISI 304) and black plastic.

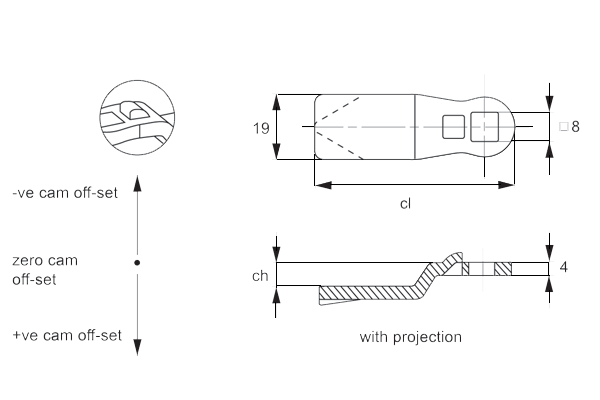

With or without "Projection"

Different cam bodies require cams either with or without projection.

With Projection Cams prevent turning of the cam over 45°, but is not suited to all cam bodies. For correct projection type, please see individual cam body technical pages.

Number of Latching Points

Single-point Cams are suitable where just single point latching is required. Multi-point cams are for applications requiring 2 or 3 latching points.

Calculation of correct cam off-set

This is the most important aspect of the selection process. As well as being with or without "projection", cams vary in two key aspects.

Cam off-set (dimension ch)

To ensure your cam fully and correctly engages with the frame of your door, the correct cam off-set must be selected. A cam off-set can be either negative (-ve) or positive (+ve).

Cam length (dimension cl)

This impacts the reach of the cam to door frame and hence impacts positioning of cam body for installation. Cam length is measured from the centre of the cam fixing hole to the cam's leading edge. Most typically cams are 45 mm in length.

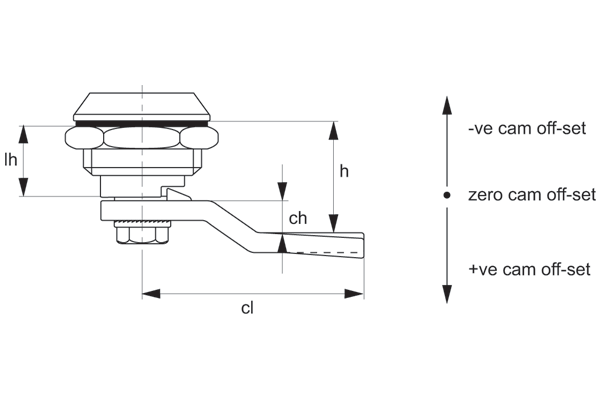

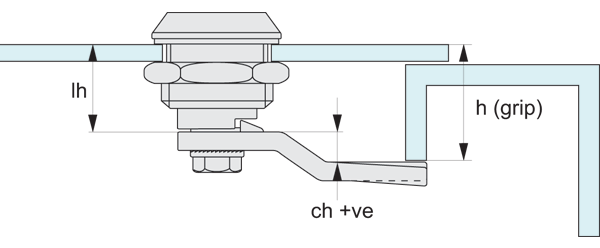

Use formula to calculate ch (required cam off-set), and refer to the cam selection chart.

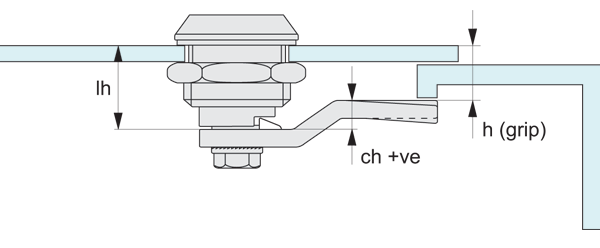

ch = h - lh where;

ch = the required cam off-set/height

h = grip length (distance between inside of latch face and front of cam)

lh = body length of cam latch/lock to be used (see example below)

Example of calculation of correct cam off-set

Example One

Cam body A1003.AW0010 has been selected for the application. If we refer to the data sheet for this part, suitable cams are parts A0203, A0210 or A0240 - "without projection".

Know application information: h=26 lh = 18

Therefore: ch = 26 - 18 =+8

Cam off-set of +8 is required.

Using the data tables for cams A0203, A0210 and A0240 we can select the following cams without projection with an off-set of +8; A0203. AW5408 (steel), A0210.AW0428 (stainless) or A0240.AW0108 (three point cam).

Example Two

Cam body A1003.AW0010 has been selected for the application. If we refer to the data sheet for this part, suitable cams are parts A0203, A0210 or A0240 - "without projection".

Know application information: h = 14 lh = 18

Therefore: ch = 14 - 18 = -4

The required cam off-set is negative, -4 as the application's door frame is effectively shorter/lower than the length of the cam body.

Using the data tables for cams A0203, A0210 and A0240 we can select the following cam without projection with an off-set of -4; A0203.AW6404 (steel).

Email Newsletter

Be the first to receive the latest news and exclusive offers via our newsletter.

Alexia House, Glenmore Business Park

PO19 7BJ Chichester

United Kingdom

0333 207 4497

sales@wixroyd.com

Route via Google Maps

Company registration no: 00496138

Company VAT number GB 408154022